FOREST MANAGEMENT, wildife,

& restoration

Acorn Forestry provides comprehensive natural resource management for private landowners, addressing both immediate needs and long-term goals. Each management plan is tailored to the landowner’s objectives while accounting for the property’s potential, limitations, and value opportunities.

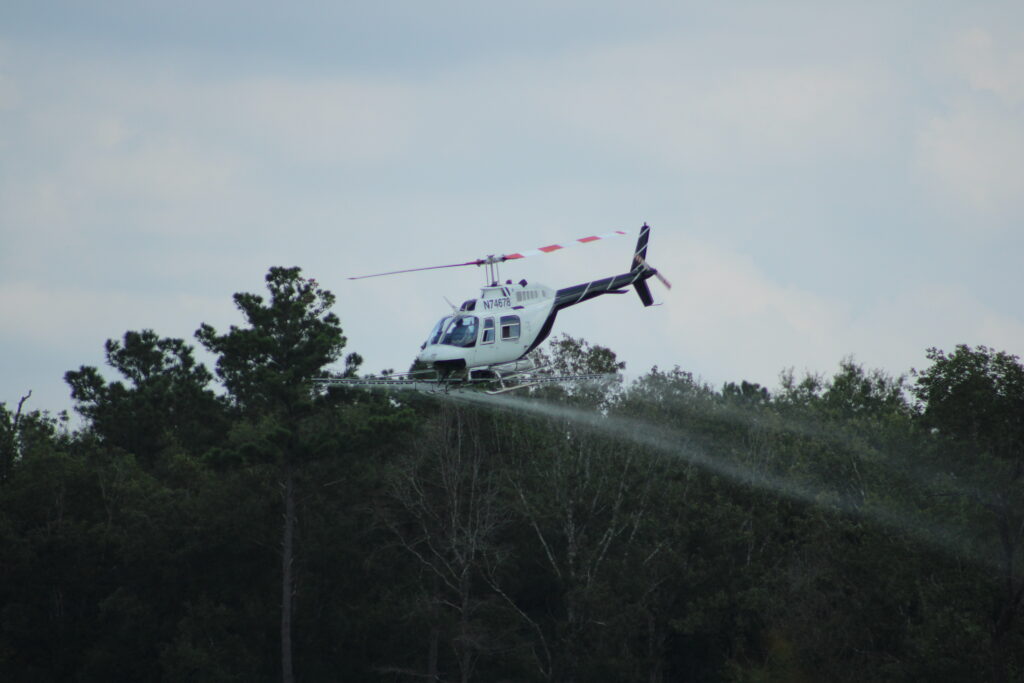

Beyond planning, Acorn executes the full range of forestry services needed to achieve those objectives. From site preparation and planting to prescribed burning, herbicide application, timber marking and sales, boundary maintenance, civil construction, and wildlife permitting, we deliver turnkey management directly in the field with the same expertise used to design it.

A timber sale is the harvest of timber products in exchange for payment. Acorn acts as the landowner’s sales agent, working with reputable buyers and loggers to secure the best value across all product classes while ensuring the harvest is performed correctly.

A timber cruise is an inventory of a stand or multiple stands of timber. Sample plots are measured for tree size and height, with notes on conditions such as disease, insects, and stocking. This data determines timber value and guides management decisions.

Timber marking is a key phase in the timber sale process—where foresters clearly identify which trees to cut and which to leave. At Acorn, experienced foresters or technicians work directly with landowner specifications and forester judgment to determine marking criteria.

Property boundaries may be fenced in developed areas, but in remote tracts they are often marked with paint. Painted lines should be established at purchase and re-marked every five years to ensure visibility, reduce encroachment risk, and maintain clarity.

Timber management plans outline strategies to meet landowner goals while sustaining forest health. These plans can increase revenue, improve wildlife habitat, or enhance recreation. Timber-focused plans emphasize long-term timber value and are typically written for ten years and revised every five.

Wildlife management plans prioritize habitat over timber, though they can still generate property revenue through hunting or ecotourism. They may also provide property tax benefits. Like timber plans, they are designed on a ten-year outlook and updated every five years.

Acorn has more than 20 years of experience in reforestation across over one million acres. Each plan is site-specific and time-sensitive, tailored to landowner budgets and often aligned with cost-share programs such as EQIP through the NRCS.

GIS mapping is a vital tool in natural resource management. Acorn provides custom maps and solutions for landowners and consultants, including aerial photographs, property maps, habitat analysis, and forest stand delineation.

Acorn offers in-house printing up to 46” wide and 150’ long in color or black and white. This service supports GIS mapping and aerial photography but is also available for posters, graphics, or project displays, with options to fit project budgets.

2. execution

WOODY RELEASE APPLICATION

HERBACEOUS WEED CONTROL APPLICATION

RIPPING

SHEARING

ECO-TIL

BEDDING

FIREBREAKS

PILE BURNS

Acorn is currently a leader among forestry companies in the southeast specializing in prescribed burning, reforestation, and timberland management. Acorn was started back in 1997 and incorporated in 1999 in Huntsville, TX.